bl

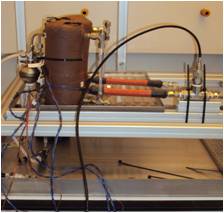

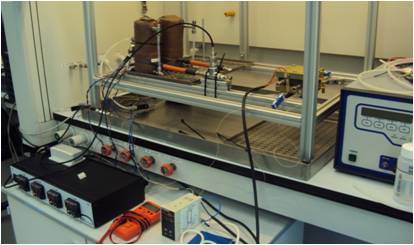

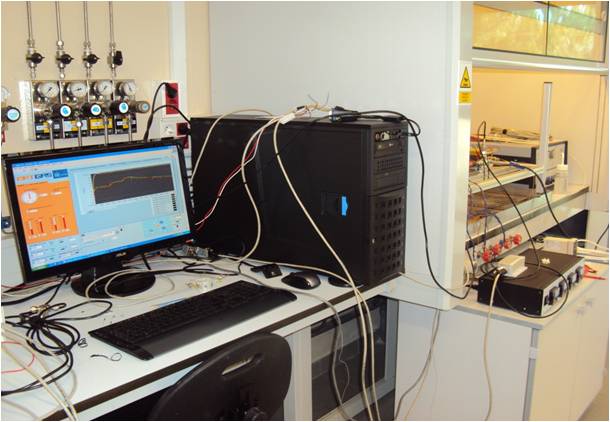

This multidisciplinary laboratory carries our both experimental and theoretical research projects. On the experimental front, research projects currently underway range from investigation of degradation phenomena occurring in hydrogen-fed fuel cell membranes and their assemblies to the development of advanced water treatment protocols utilizing state-of-the-art ozone, advanced oxidation and peroxide techniques. On the theoretical front, we are developing advanced control strategies aimed at maximizing the efficiency of a number of industrially important processes.

Assigned personnel

|

|

|

Sonia Guri

Technical Lead

Water treatment |

Related research lines

|

Materials for Energy |

CO2 utilization |

Water treatment |

Available equipment

| Equipment Description | Features | Main Applications | |

| Glove Box |

Exterior chamber for easy access Purge/Fill cycles Gas recirculation Gas purification. |

Manipulation of air sensitive materials in inert atmosphere. Reductive reactions Storage of materials |

|

| Hei-VAP precision Rotary Evaporator |

Temperature range: -10ºC to 40ºC. Cooling liquid capacity: 2 l. Max. delivery (pressure): 20 l/min. Max. delivery (suction): 17 l/min. Mains voltage: 230V/50Hz or 115V/60Hz. Power rating: 600 W. Weight: 32 kg. Admissible ambient conditions: 5-32ºC and 80% relative humidity in the air. |

Distillation or evaporation of solvents. Purification of chemicals, mixtures and preparations. Processing batch reactions. Impregnation of organic species on suitable solid substrates. |

|

| High temperature tubular furnace | 1200°C maximum operating temperature. Long life, rapid heating, resistance wire elements mounted in rigid, vacuum formed insulation modules. Carbolite301, PID controller with digital set & display. Delayed start / process timer function as standard. Horizontal configuration. Furnace mounted directly on top of controller base unit. Over-temperature protection. Purge gas flow control. |

Testing of novel materials under strict temperature and varying atmosphere conditions. Testing electronic components and semiconductor materials under inert atmospheres. Testing of temperature sensors such as thermocouples which may require enhanced thermal uniformity. |

|

| VMP 3 Potentiostat |

Number of channels: 5 Current ranges: 6 different ranges: ±10μA to ±1A (100kΩ to 1Ω) 4 low current ranges in 2 channels: ±1nA to 1μA (1GΩ to 1MΩ) Complex impedance measurements: 2 channels (10μHz to 500kHz) Control Voltage Range: ±10V adjustable to 0-20V Maximum current: 8A (internal booster) Equipped with EC-Lab® software. |

Basic electrochemistry Voltammetry Corrosion Waveform programming Sensors Fuel cell and battery testing Complex impedance measurements. |

|