The Nanotechnology laboratory is equipped for the characterization and manipulation of materials at nanoscale by employing SPM techniques (AFM and SNOM), particle size measurement, micro-Raman scattering, nanocalorimetry and nanoindentation. This laboratory allows a comprehensive study of the properties of nanostructured materials, including size, mechanical, thermal, optical, structural, and electrical properties.

Assigned personnel

|

|

|

|

Related research lines

|

Materials for Energy |

CO2 utilization |

Available equipment

| Equipment Description | Features | Main Applications | |

| Raman Spectroscopy | Micro and macro Raman. Motorized XY mapping stage. Confocal optics. Visible and IR laser lines. Detectors: CCD / NIR. High pressure cell. Cryogenic stages. 800mm focal length spectrometer. LN2 cooled CCD FIVS. SuperNotch filters. 488 nm, 514 nm, 633nm, and 825 nm. |

Pharmaceuticals: polymorphism, mapping of active ingredients. Semiconductors: stress, composition, nanostructures. Solid state: chemical reactions in composite materials, corrosion, mapping of composites. Bilology: provides a biochemical fingerprint of lipids, proteins, bacteria,... |

|

| Pico + AFM |

Imaging in fluid: AC mode, top-down scanners, and inert electrochemical cells. Fluid handling, sample exchange and sample-cell cleaning with fluid cell. |

Nanoscale Electrochemistry Nanomaterials/Polymers /Coatings/Bio Lithography Characterization of surfaces via electro-chemical, conducting properties or just standard AFM/STM imaging |

|

| Triocular microscope | Triocular head. Continuous zoom Magnification: 14x – 90x Computer controlled CCD for image and video acquisition. Pentax camera for high resolution image acquisition. Triple illumination system. |

Surface characterization. Sample manipulation and preparation. Image acquisition (photo and video). |

|

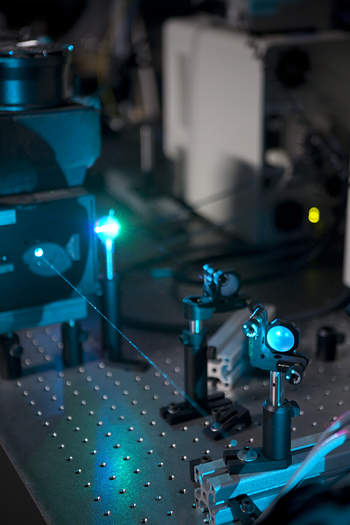

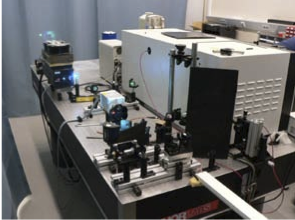

| Scanning Near-field Optical Microscopy (SNOM) |

Tuning fork shear-force feedback |

Emulsions, suspensions and dry powder in pharmaceutical industry. Analysis of toxic materials and high-value sample materials. Chemicals, foodstuffs, cements and starches that change with hydration, metal powder, minerals, powder coating and dry ingredients. |

|

| Nanoindenter XP | Min displacement resolution: < 0.01nm Total indenter travel: 2mm Maximum indentation depth: > 500 μm Maximum load: 500 mN Load resolution: 50 nN Pieco resolution/repeatability: 0.01nm LFM resolution 10 μN High precision tables, accuracy better than 0.5 μm Nanovision: imaging the surface using the indentation tip, few nanometers accuracy. Continuous stiffness measurement Scratch testing Lateral force measurement Complete access to system components by TestWorks Explorer level |

Thin film characterization Probing small volumes of material Mapping out mechanical properties Hardness and modulus as a function of indentation depth - dynamical measurements |

|

| Low-T Nanocalorimeter | Temperature range: 4,2-500 K Vacuum: < 10-6Torr Measurements performed on previously microfabricated devices. Ideally suited for thin films. Heat capacity analysis of ultrathin films (mass down to pg) using adiabatic mode at fast heating rates. AC calorimetry. Thermal conductivity measurements on thin films or multilayers. Compatibility with simultaneous optical measurements. |

Analysis of heat capacity in nanoscale systems. Influence of interfaces and low-dimensionality. Phase transformations related to size-dependent phenomena. Thermodynamic properties of thin films and nanoparticles. Glass transition in thin or ultra-film polymeric systems. Thermal conductivity in low- dimensional systems. |

|

| Mastersizer 2000 | Measurement principle: Mie scattering. Detection systems: Red light: Forward scattering, side scattering and back scattering. Blue light: Wide angle forward and back scattering Wet dispersion Hydro μP 18ml: thermal controlled unit agitated by a impeller pump and high efficiency ultrasonic disperser Hydro MS 50-120 ml: stirrer and a variable shaft pump Dry dispersion Sirocco 2000: controlled by dispersive air pressure (0-4bar) |

Emulsions, suspensions and dry powder in pharmaceutical industry. Analysis of toxic materials and high-value sample materials. Chemicals, foodstuffs, cements and starches that change with hydration, metal powder, minerals, powder coating and dry ingredients. |

|

| Turbiscan LAb | Multiple Light Scattering. Backscattering and transmission. Backscattering at 135o Optical sample volume: 20ml Particle size range 0.1μm - 1 mm Temperature controlled: 5 – 60oC Dispersive stage Monitoring Non destructive sampling Easy sample preparation. |

Stability studies of emulsions, suspensions and foams. R&D Analysis Quality control (Beverage, Cosmetics, pharmaceutical) |

|

| Zetasizer Nano ZS | Size measurement Particle size range: 5nm to 10μm Sample volume range: 12 μl to 20μl Zeta measurement Particle size range: 3nm-10μm Minimum sample volume: 0.75ml Molecular weight measurement Molecular weight range: 103 to 2·10(7) Da Minimum sample volume: 20μl Temperature range: 2 to 90oC NIBS method measurement Laser: 4mW He-Ne 633 - Automatic attenuation |

Characterization of solids and dispersed system (suspensions, emulsions and liposome) Proteins and polymers analysis and characterization Pharmaceutical products, Nanoparticles, optoelectronic, emulsion stability. Water Treatment, pigments properties and impurities determination. |

|

matgas.org

matgas.org